I have read the Privacy Policy

The collected data will be used exclusively to answer the request.

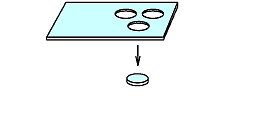

1.Electrde Sheet

Activated charcoal and binders are mixed and formed into a sheet.

2.Punching

Disks with specific diameters are punched out of the electrode sheet.

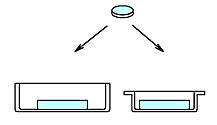

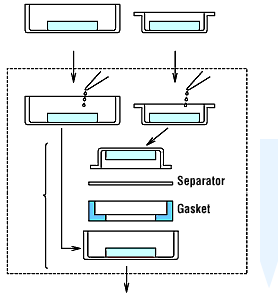

3.Adhesion

A conductive adhesive is used to adhere the electrodes punched from the sheet to the metal case and cap that will form the capacitor.

4.Electrolyte Fill

After drying, the case and cap (with the electrodes glued inside) are filled with an organic liquid electrolyte inside a dry box.

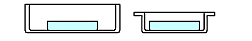

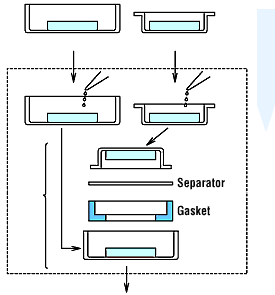

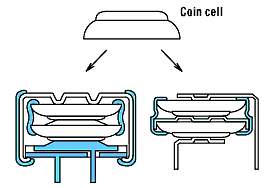

5.Assembly / Sealing

The case and cap are assembled together with a separator and a gasket, and the case is crimped in a case to seal the opening, forming a coin cell.

6.Cell Test

100% of the coin cells are subjected to electrical testing.

7.Layering

Because the withstand voltage of the individual coin cells is between 2.8 and 3.0 V, two or three of these cells are connected in series.

8.Test

9.Shipping

1.Manufacture of Coating

A slurry of the coating material is made by mixing activated charcoal, solvents, and other materials.

2.Coating

Aluminum foil is coated with the activated charcoal material to make activated charcoal electrodes.

3.Slit

Aluminum foil is coated with the activated charcoal material to make activated charcoal electrodes.

4.Lead Attachment

Leads are attached through either crimping or ultrasonic bonding to form contacts with the cathode and anode foil layers.

5.Coiling

Electrolytic paper layers are coiled between the cathode and anode foil layers, separating the conductive layers, during coiling to form the "element."

6.Wetting

The element is wetted with an electrolyte using, for example, a lower pressure to drive the fluid into the element.

7.Assembly

After wetting, a rubber seal is put on the leads and the element is inserted into the case.

8.Sleeve Attachment

A sleeve printed with the rated voltage, capacitance, characteristics, etc., is heat-shrinked onto the capacitor.

9.Aging

The rated voltage is applied, to age (debug) the components.

10.Final Test / Inspection

100% of the units are subjected to electrical testing and visual inspection, and the infant mortality failures are removed.